Mendocino motor

Solar motor with levitating rotor

Online since: 19/05/2010,

Number of visits: 830542

2

Manufacturing process for Mendocino motor

The first piece of the rotor is done.

Later, the coil wire will be wound into the notches in the corners.

The solar panel is mono-crystalline and has a maximum current of approx.

200 mA at a voltage of approx.

0,5 V.

This translates into a maximum power of approx.

0,1 Watt.

The match shows the small dimensions of the motor.

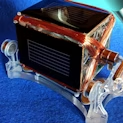

Here you can see the finished glued rotor.

The axle is made of acrylic glass since I couldn't find round polycarbonate rods.

I glued a steel sphere (1,2 mm diameter) into the tip (right).

It is hardened, offering durability with little wear and tear.

I put two R-10-04-05-N

ring magnets on the front and the back of the rotor, respectively.

I used a Q-40-20-05-N

block magnet for a stator, which I embedded and glued into an acrylic glass plate.

In this picture, you can clearly see the dark wood inlaid (marquetry), which I added for aesthetic reasons.

I embedded a small wooden plate and a tiger's-eye on the side.

This semi-precious stone constitutes the counter bearing to the steel sphere of the rotor.

That's basically an inlaid work in the inlaid work.

The stone has a Mohs hardness of 6-7.

So, it should last for a while when the rotor peak rests on it.

Mini Mendocino motor

Addition from Alain Gleyzes (2015): My goal was to build the world's smallest 3D-printed Mendocino motor. Instead of one large block magnet, I used four disc magnets and needed only two ring magnets due to the light weight.You can find a detailed documentation of the assembly at Thingiverse.com.

Parts of the Mendocino motor

I used the following material:- 2 carbon tubes (kite shop) or 2 wooden rods (12 x 0,3 cm)

- 4 solar cells

- 1 coil enamelled copper wire (0,2 mm)

- 4 disc magnets 12 x 3 mm

- 2 ring magnets 10 x 4 x 5 mm

- 1 pen tip

The entire content of this site is protected by copyright.

Copying the content or using it elsewhere is not permitted without explicit approval.

Copying the content or using it elsewhere is not permitted without explicit approval.